Winter is coming, please check the fiber laser source anti-freezing measures

In the winter, many people don’t know how to protect fiber laser equipment from freezing? Today, Shandong Reaying Machinery Co., Ltd. will share with you the anti-freezing measures for fiber laser cutting machines. Only when you are familiar with the antifreeze measures can you better protect the core components of the laser equipment and make the laser equipment work better.

Laser operating temperature requirements

The working environment temperature of the laser cutter shall be controlled at about 22 degrees. The low temperature water temperature of the water cooler shall be set at 20-24 degrees and the high temperature water temperature shall be set at 28-30 degrees. Before the laser light comes out, the water cooler shall work for more than 20 minutes to ensure that the actual temperature of the water cooler reaches the set temperature.

Basic principle of antifreeze

There is a “freezing point” in the cooling water. When the temperature of the cooling water is lower than the “freezing point”, the volume expansion of the cooling water during solidification will lead to the expansion and deformation of overflow components in the laser cooling system, such as cold-water plate, water separator and other components, expansion crack and optical device damage, resulting in the return of the laser for maintenance. Therefore, anti-freezing protection measures for the laser in winter must be taken to ensure the normal operation of the equipment.

Antifreeze solution:

1 – keep the chiller running

Under the condition that there is no local power failure, the chiller can be kept running, and the low-temperature water and normal temperature water can be set at about 5 ℃ (ensure that the cooling water is higher than the freezing point and save electric energy).

2 – drain the cooling water in the machine

After each use, drain the cooling water in the laser and water cooler.

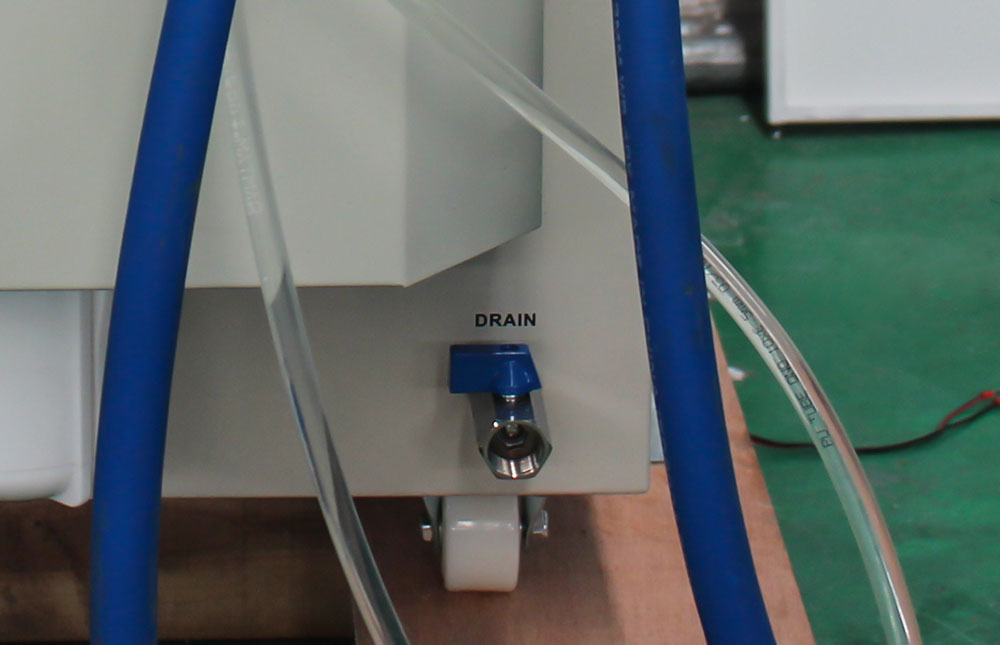

Drainage method:

Turn off the power of the water chiller, open the drain valve at the back of the chiller, and drain the water in the water tank. Remove the water inlet pipe from the chiller, and then use compressed gas (0.2Mpa) to ventilate the water inlet (WATER IN) until the residual water in the chiller is blown out.

Remove the water pipe of the water inlet from the laser source, and then ventilate the water inlet (WATER IN) with compressed gas(0.2Mpa) until the residual water in the water cooling pipe inside the laser is blown out from the water outlet. Then plug the water inlet and outlet with a water pipe (or rubber plug) to prevent dust from entering the water pipe.

3—Use antifreeze to replace cooling water

When the use environment is often out of power and does not have the conditions to drain the cooling water every day, antifreeze must be used.

The choice of antifreeze

- Please choose an antifreeze with a suitable freezing point according to the local temperature. The choice of antifreeze is not that the lower the freezing point, the better, but according to the local minimum temperature, you can choose an antifreeze that is slightly lower than the local temperature.

- Shandong Reaying Machinery Co., Ltd. recommends that the water cooler antifreeze is the American Clariant brand.

mixture ratio

Local temperature: – 42 ℃ ~ – 45 ℃ (60% antifreeze and 40% pure water)

Local temperature – 32 ℃ – 35 ℃ (50% antifreeze, 50% pure water)

Local temperature – 22 ℃ ~ – 25 ℃ (40% antifreeze and 60% pure water)

Local temperature: – 12 ℃ ~ – 15 ℃ (30% antifreeze and 70% pure water)

Notice:

- Any antifreeze cannot completely replace deionized water, and it is not recommended to use it for a long time throughout the year. After winter, it is recommended to clean the pipeline with deionized water or distilled water, and restore the use of deionized water or distilled water as coolant.

- If the equipment is shut down for a long time or before the laser is transported, the cooling water in the equipment must be drained, and the residual water in the equipment (including laser and chiller) must be blown away with compressed air to prevent internal icing from damaging the device.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More