Tips for resuming work: Guide to resuming laser work after the holidays

Laser equipment generally has a long downtime during holidays. To help you resume work quickly and smoothly, we have carefully prepared a resumption guide. As long as you unlock it correctly, you can produce efficiently and help you get back to work!

Warm reminder: If the equipment manufacturer has more detailed instructions, this resumption guide can be used as a reference document and can be unlocked and implemented as appropriate.

Level 1: Safety Matters

Make sure power and water are cut off

(1) To ensure the safety of personnel and equipment, ensure that the main power supply of the laser system and water cooler is disconnected, and live work is strictly prohibited;

(2) Close all water inlet and outlet valves of the water cooler.

Warm reminder: Do not point your eyes towards the direction of the laser at any time.

You have turned on safe mode and successfully unlocked the second level ↓↓↓

Second level: System detection and maintenance

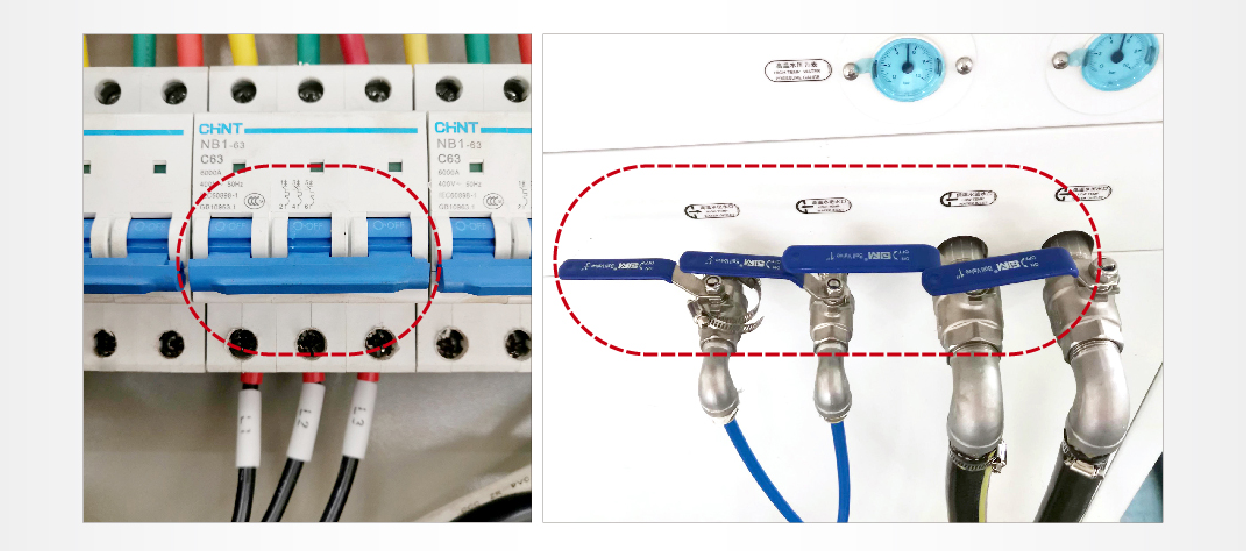

- Power supply system

(1) Power supply line: no serious bending, no damage, no disconnection;

(2) Power cord connection: press the plug to ensure the connection is firm;

(3) Control signal line: The interface connection is firm and not loose. - Air supply system

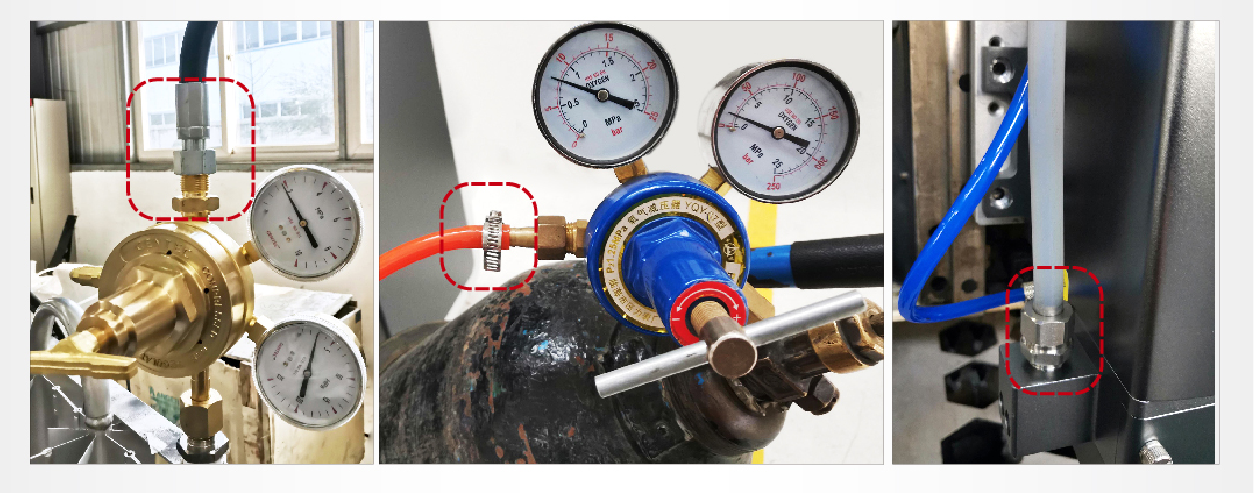

(1) Gas pipeline: no damage, no blockage, good air tightness;

(2) Tighten the joints of each gas pipeline to ensure that the connection is firm and smooth;

(3) Use standard gas according to the equipment manufacturer’s requirements. - Water cooling system

(1) Confirm again to close the inlet and outlet valves;

(2) Water tank/water pipe: no bends, no blockages, no damage, do a good job in cleaning the water tank and water pipes;

(3) Tighten each water pipe joint to ensure that the connection is firm and smooth;

(4) When the temperature is lower than 5℃, you need to use heating equipment to blow the internal pipes of the water cooler for a period of time to confirm that there is no ice;

Warm reminder: If the equipment is shut down for a long time in an environment below 0℃, you need to carefully check whether the cooling water pipe has frozen or signs of freezing. If found, be sure to contact the equipment manufacturer in advance to avoid greater losses after operation!

(5) Inject the specified amount of distilled water into the water cooler and let it sit for 30 minutes to ensure that there is no sign of water leakage;

Warm reminder: If the temperature is below 5℃, antifreeze must be diluted and added in the correct way.

(6) Turn on the power switch of the water cooler and keep the power of other equipment off;

(7) Open the water inlet and outlet valves of the water cooler a small amount, run the water cooler, circulate the cooling water from the laser and optical head back to the water tank at a low flow rate, and drain the excess air in the water loop pipe. It is recommended to complete this process within 1 minute;

(8) Mark the water level position of the water tank, let it sit for 30 minutes again, observe whether the water level changes, and again ensure that there is no leakage in the internal pipeline;

(9) When the above confirmation is correct, re-run the water cooler, open the water valve normally, wait for the water temperature to reach the set temperature, and prepare for the operation of the equipment.

God, this guy is so handsome! Enter the third level immediately ↓↓↓

The third level: equipment operation detection

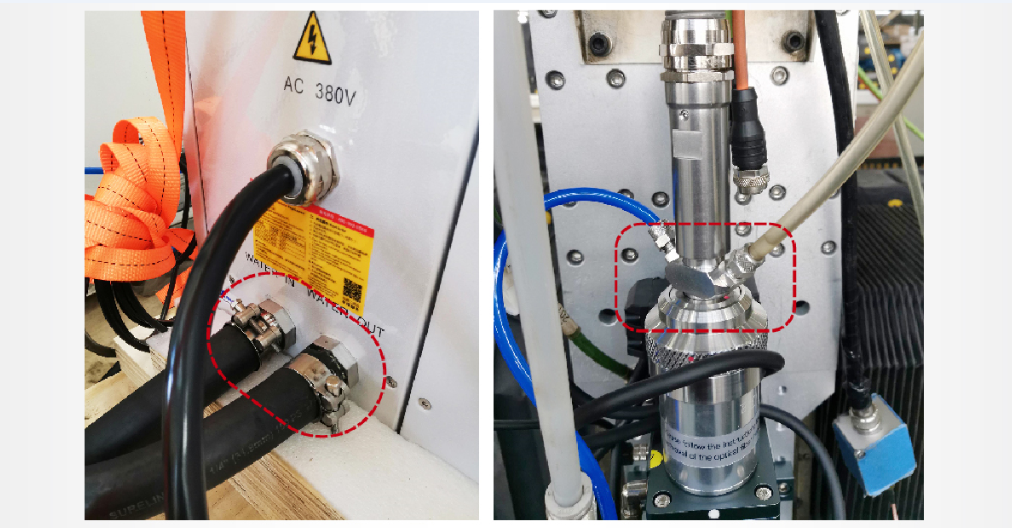

- Power on the device and run it

(1) Confirm that the water temperature of the water cooler has reached the set temperature;

Warm reminder: The speed at which the water temperature rises is related to whether the water cooler has a heating function.

(2) Turn on the power switch of the laser processing system. After the laser is powered on, the POWER indicator light on the laser panel will light up.

Warm reminder: Check the optical circuit first. Do not emit light or process directly for the time being. After starting the laser, observe whether each indicator light is normal and whether there is an alarm. If an alarm occurs, you can connect to the laser monitoring software to view the alarm information and contact the equipment manufacturer! - Detection before light emission

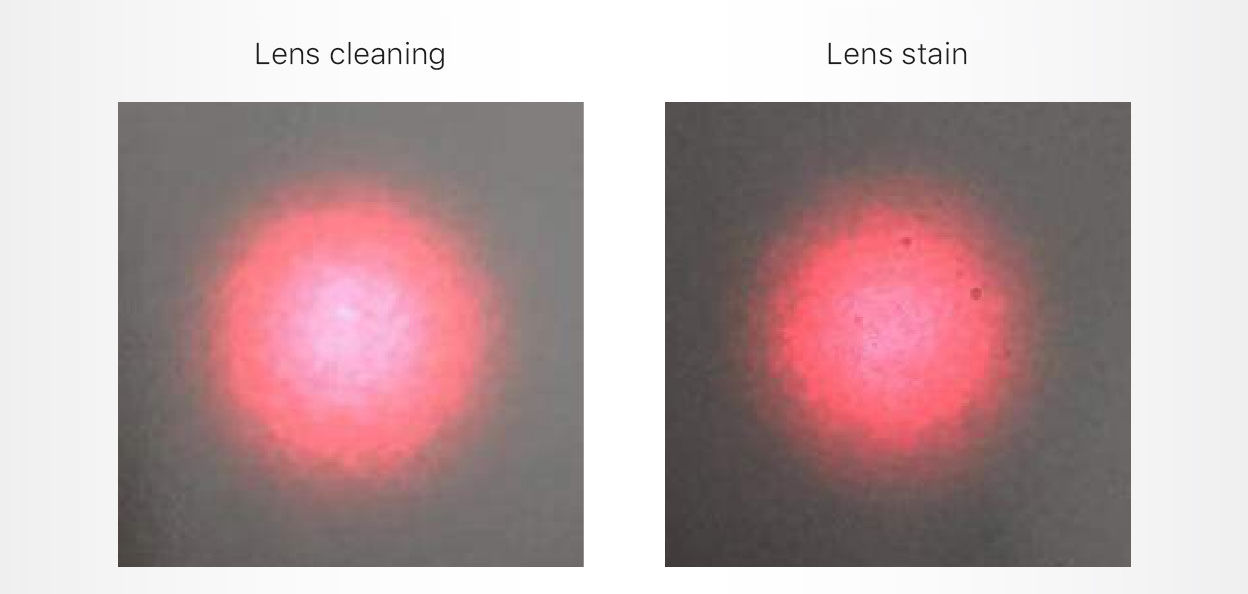

(1) Use red light detection method to check lens cleanliness

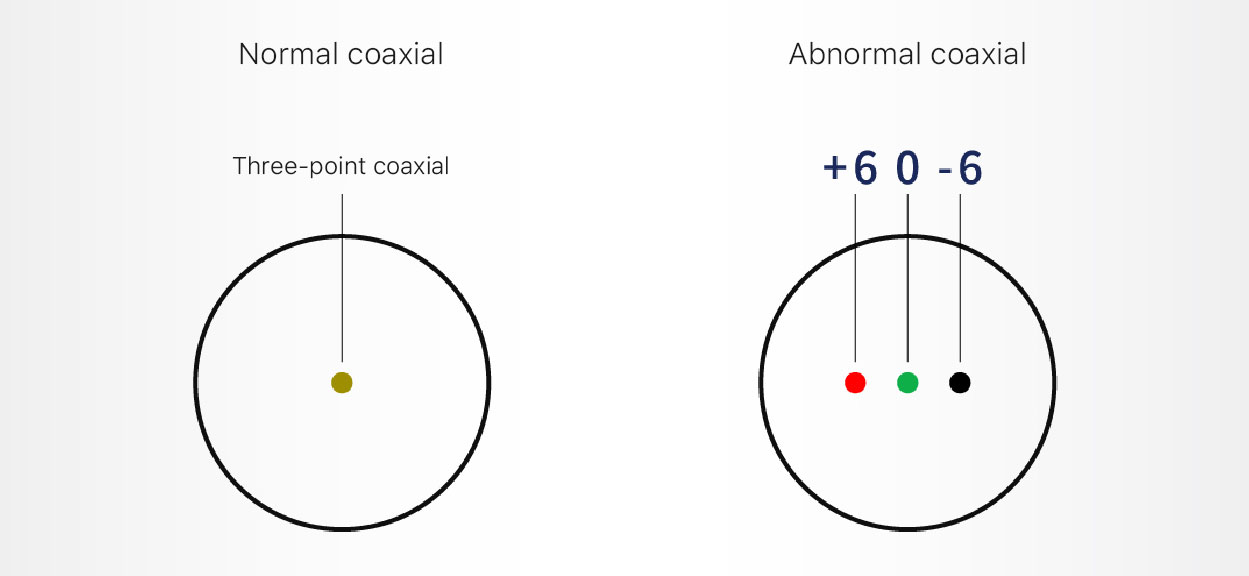

(2) Coaxial test: Judge the coaxiality of the nozzle exit hole and the laser beam according to the standard below

Test results: No abnormalities.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More