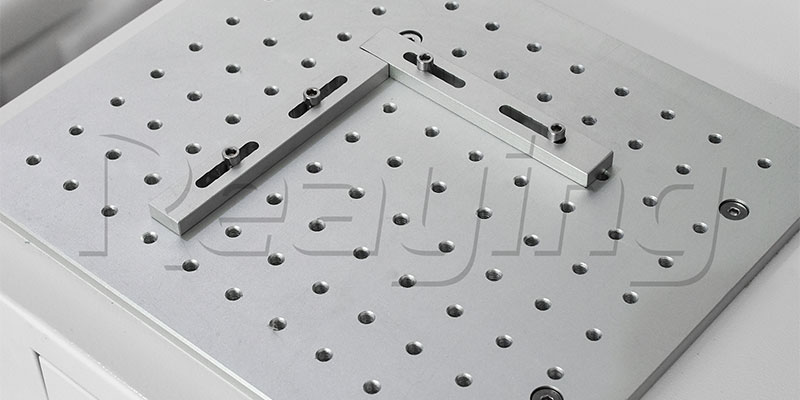

Sophisticated method of fixing the workpiece in place when operating the laser marking machine

Running operation, there have been a cause of all the operators are very troublesome problem is, I believe that many operators have encountered similar problems, it is placed on the workpiece and the problem fixed. For this more difficult issues, come up with their own programs, there is nothing, there are also hard to get the problem solved when.

Specific method is like this, by the principles of post-processing operations are analyzed, from which we learned that the relative movement of the operation is the Cartesian coordinate system and workpiece spot progresses, it can be divided into three ways you can run a workpiece movement; two spot movement; Third, the two combined movements. Spot movement is relatively simple but it is dominated by fixed light guide system controls for processing small area mainly uses two-coordinate table moves the workpiece, and let the fixed optical path may be the best solution;, but the size of the workpiece surface machining larger than the heavy case, we often use the mirror, optical processing top part fixed on the move together with the gantry or rail.

At this time, the same two operational programs: There actually used to allow more fixed gantry, allowing processing units driven workpiece coordinate moves, so relatively simple. But if you need to synchronize the movement of the gantry is driven from both sides but the structure is more complex. For large parts, large format products heavier Lee case, then as far as possible to resolve the points of light exercise program. Meanwhile, in order to avoid over-coherent state laser processing spotted change is too large, fixed laser can be moved together to make progress on the rail. Also note that a variety of purposes:

- stability of the laser installation

- firmness and stability of the gantry and moving parts

- lubricating rails

- relatively horizontal position

- light sensor reliability and so on.

Metal laser marking machine motor Why fever?

As we all know, any motor will heat, but nothing different degree fever.

Laser marking machine in the work process is very easy to heat, which is due to its performance decision.

Everyone should know that directly affect the stability of the current operation of the motor, if the current is not a standard DC or sine wave, but also produce harmonic losses, the core has a hysteresis eddy current effects.

In alternating magnetic field will produce losses, its size and materials, current, frequency, voltage dependent, called iron loss.

Copper and iron losses are manifested in the form of heat, thus affecting the efficiency of the motor.

More electrical energy into heat, so the laser industry, if the current instability, greatly reducing the metal laser marking machine efficiency.

Cause metal laser marking machine electrical heating of serious problems, if not handled properly, it is likely even lead metal laser marking machine motor burned out, the overall state of paralysis.

How the laser marking machine laser beam to adjust to the best state? Following, for your reference learning.When the laser beam scanning galvanometer away from the origin is set, then the appearance of the workpiece is no longer the focal plane of the laser beam (which is a spherical focal plane, the outer plane of the workpiece), where the spot becomes large aggregates, so that Marking the spot diameter entire workpiece is not on the same plane, marking the line width is not the same.

Laser marking machine symbols method has no need because the inks and solvents, environmental adaptability, and can be manipulated by computer sensitive symbol shape and content, and could have symbolic data density.

High speed and accuracy characteristics of the symbol, its use is expanding the scale, especially in the use of mobile phone accessories and electrical enclosures are moving rapidly throughout.

However, the laser method is flawed symbol, as carried out in the appearance of clear plastic laser symbol, material requirements specially selected additives appropriately modified.

Currently the most widely used plastics can choose fiber laser marking machine symbols. See the red laser is not coincident with the paper as laser output mirror is fixed in front of the mirror and try to stay away from the output direction, announcing a laser pulse.Surveys like the paper spot center is not coincident with the red center, if not overlap, can fine-tune the output mirror and full mirror, so that coincides with the red spot.

Then fixed on the ground like paper from the laser output mirror 800 ~ 1000mm, once again see the light spot is not coincident with the red light. As can better coincidence that the laser is adjusted to the best condition.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More