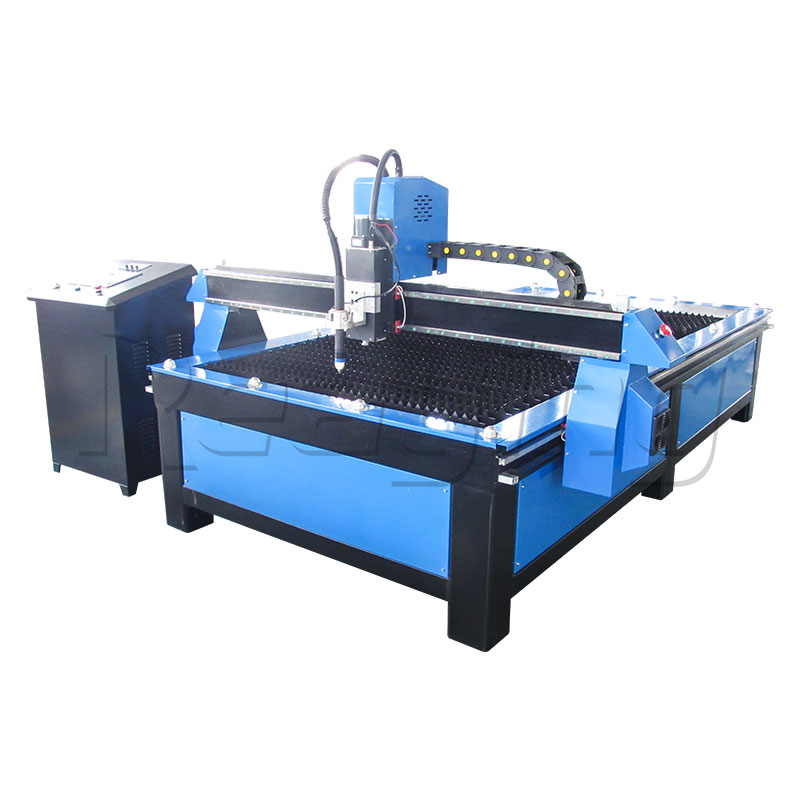

Plasma CNC Cutting Machine RY-L1325P

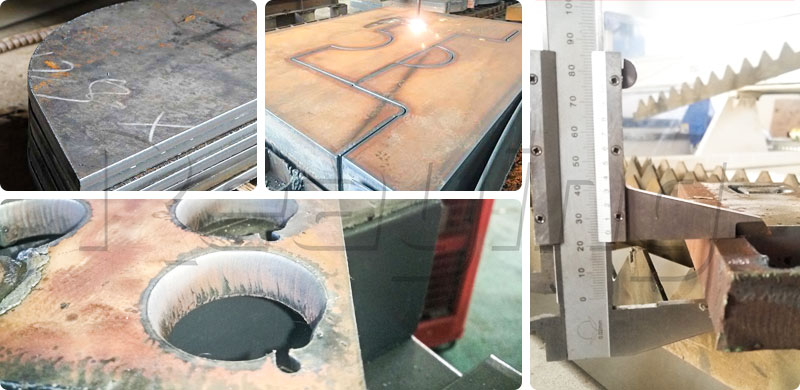

Air plasma cutting machine is a new type of thermal cutting equipment. Its working principle is to use compressed air as the working gas, high temperature and high-speed plasma arc as the heat source, to locally melt the metal being cut, and at the same time to melt the molten metal with high speed airflow. Blown away, forming a narrow slit. This equipment can be used for cutting various metal materials, not only with fast cutting speed, narrow slits, flat cuts, small heat affected zone, low workpiece deformation, simple operation, but also significant energy saving effect.

Model:

RY-L1325P

Function:

Cutting

Input Voltage:

Custom Made

Power Source:

HUAYUAN, HYPERTHERM(US Brand)

Positioning Accuracy:

±0.1mm

Working Area:

1300*2500mm

Machine bed

The machine bed is processed by precision machine tools and aging treatment, which is firm, reliable and durable.

86 high torque motors and drives

Gantry structure, using double linear guides and high torque stepper motor, enables the machine to run smoothly with high precision. Fast cutting speed, high precision and low cost.

If you have high requirements for accuracy, you can choose the Japanese Yaskawa servo motor.

Beijing Starfire control system

Our machine equipped with Beijing Starfire control system which widely used in metal processing, advertising, stone and other industries.

With anti-plasma interference, anti-lightning and surge capabilities. During plasma processing, corner speed control and height control are automatically completed; wireless remote control can be used for remote operation.

It has the function of slit compensation, and checks whether the compensation in the program is reasonable, and makes corresponding reports for users to choose.

Breakpoint recovery, automatic power-off recovery function, breakpoint automatic memory.

Fully compatible with StarCAM nesting software, and compatible with mainstream nesting software such as IBE (Germany) and FASTCAM.

Multi-language operation interface conversion, dynamic graphic display, 1-8 times graphic zoom, automatic tracking of moving points, U disk reading program and timely software upgrade…

Beijing Starfire SF-HC25K height controller

The display of set and actual arc voltage is simple and intuitive.

The torch anti-collision function, when the cutting nozzle touches the steel plate, the controller will quickly lift the cutting tool by a certain distance, effectively protecting the cutting nozzle.

Power Supply

We chose HUAYUAN Power Supply and HYPERTHERM Power Supply, which have reliable performance, excellent cutting quality and fast cutting speed, significantly improving production efficiency and greatly reducing operating costs.

Technical Parameters

| Model | RY-L1325P |

|---|---|

| Working area | 1300*2500mm, 1500x3000mm optional |

| Plasma Current | 63A/100A/120A/160A/200A/300A |

| Z axis travel | 100mm, 130mm, 150mm optional |

| Positioning accuracy | ±0.1mm |

| Warranty | 3 YEARS |

| Source brand | Power | Carbon steel | Stainless steel |

| HUAYUAN | 63A | 10mm | 5mm |

| 100A | 12mm | 6mm | |

| 120A | 19mm | 10mm | |

| 160A | 25mm | 15mm | |

| 200A | 45mm | ||

| 300A | 50mm | ||

| 400A | 60mm | ||

| US Hypertherm | 45A | 6mm | 3mm |

| 65A | 10mm | 5mm | |

| 85A | 12mm | 6mm | |

| 100A | 19mm | 10mm | |

| 200A | 32mm | 16mm |

Applications:

Mainly used for manual and machine cutting of carbon steel, alloy steel, non-ferrous metals and other metal materials

Widely used in boiler chemical industry, pressure vessel manufacturing, industrial power station installation, metallurgical construction, chemical construction, aerospace industry, automobile manufacturing and maintenance, building decoration and other industries that involve metal cutting

Get Free Inquiry Now

We will contact you as soon as possible!