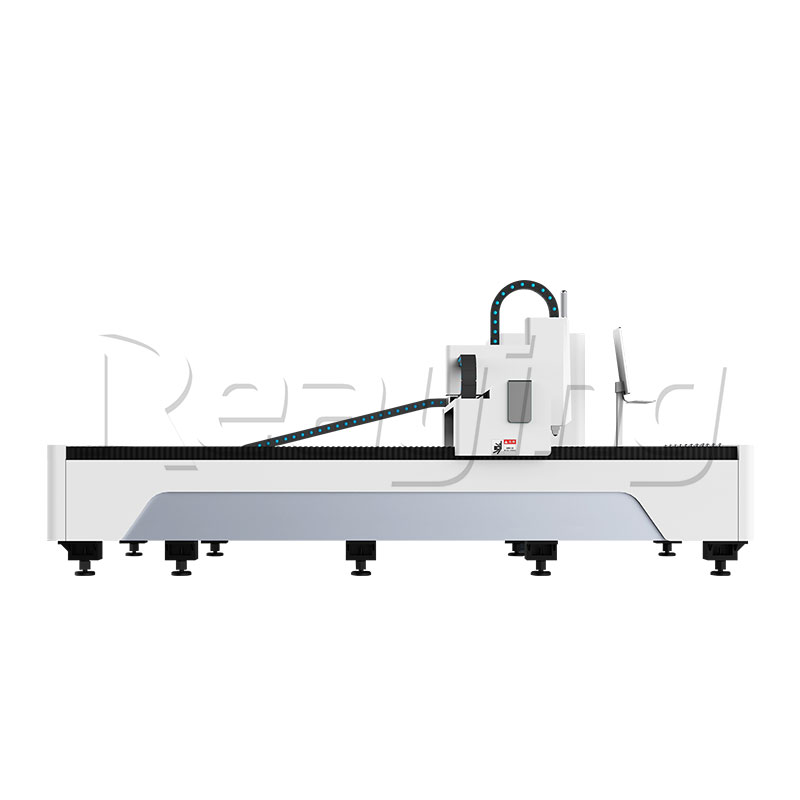

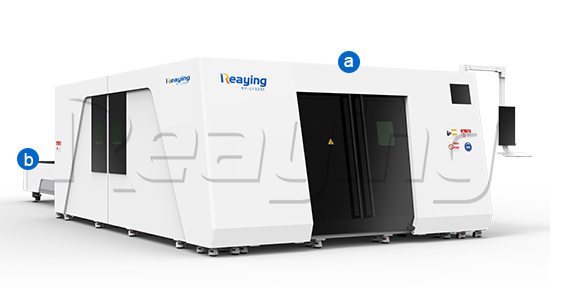

Fiber Laser Cutting Machine RY-L1530F Focus On Metal Sheet Cutting

Reaying fiber laser cutting machine RY-L1530F series are fiber laser cutting machines which focus on cutting sheet metal.Fiber laser cutting machine RY-L1530F series are applied in auto industry, kitchen and bathroom industry, etc.

Model:

RY-L1530F

Function:

Cutting

Input Voltage:

Custom Made

Laser Power:

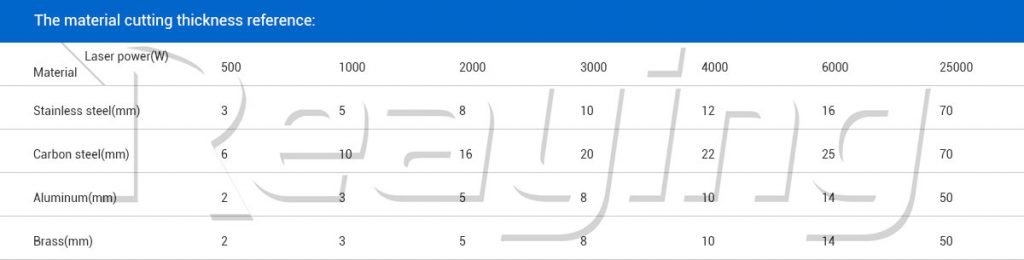

500W-25000W

Laser Source:

Genuines Raycus

Working Area:

1500*3000mm

Intelligent alarm light, real-time display of working status

Customized Pad-type vertical screen display, vertical screen display, fast response, high resolution, high contrast, tempered glass panel is durable

Independent control cabinet,electrical components, industrial computer and laser are built in a separate cabinet with dustproof design. The cabinet is equipped with a constant temperature dehumidification industrial air conditioner to ensure long-term operation of the equipment throughout the year.

Heavy-duty cast iron bed, stable and durable

The fiber laser cutting machine has a very high requirement for the bed. The Reaying cast iron bed weighs 3 tons and ensures no deformation for 60 years. It has the following characteristics:

1. The cast bed is made of gray cast iron with flake graphite, which has excellent vibration damping, low notch sensitivity and high wear resistance.

2. Casting the bed body, integrated molding, after aging, eliminate the internal stress, thereby improving the surface hardness, corrosion resistance and stability, so that the precision of the cutting machine is maintained for a long time.

3. Compared with the ordinary welded bed, the cast bed is much heavier, the machine vibration is small, and the cutting precision of the equipment is improved.

4. The bed will inevitably have an unexpected gap in the transportation process. The cast iron bed has the characteristics of extremely low notch sensitivity, which ensures the comprehensive stability of the bed.

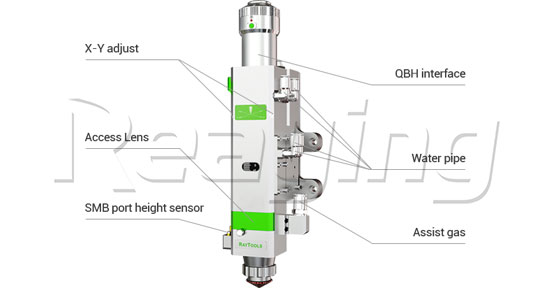

Swiss Raytools brand auto-focusing cutting head, good horses should be equipped with a saddle,

It adopts imported closed-loop motor, high-speed perforation and cutting of various material thickness plates, and the repeating precision is 0.01mm.

Automatically find the best focal length instead of manual focusing, the adjustment range is -10-+10mm. The focusing speed reaches 400mm/s, more efficient

IP65 dust-proof design, fully protect internal optical components and extend service life.

Built-in collimating lens focusing lens double water cooling structure, reducing the temperature of the cutting head and prolonging the service life of the cutting head.

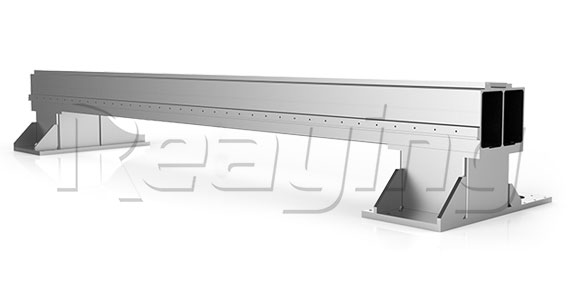

Aviation standard aluminum gantry, small graphic cutting is more perfect.

The aluminum gantry extruded by a 4,300-ton press that meets the aviation standard has higher hardness, corrosion resistance and excellent oxidation resistance after aging.

The weight is only 1/2 of the traditional welded steel beam, the quality is light, the speed is fast, the precision is high, and the processing speed is greatly improved.

Compared with cast aluminum gantry, aviation aluminum gantry eliminate casting defects such as sand holes and have better overall performance.

Japan imported dual servo motor synchronous drive system, stronger power, stable and reliable

It has the highest amplifier responsiveness in the same industry, which greatly shortens the setting time, realizes acceleration and deceleration at high speed, and has fast response.

Low heat, low noise, high speed and high precision.

Strong anti-interference ability and strong anti-overload capability.

There is automatic adjustment mode, if the effect is not good, it can be adjusted more conveniently.

Adopting Japan Nidec-Shimpo reducer, adopting helical gears, low noise, high rigidity and high assembly precision

Mute: Smooth, quiet operation with anti-vibration, low-noise planetary gearbox construction and helical gears

High precision: High precision, backlash 0.05 (3 points), with output shaft, free to install, high rigidity.

High torque: The Nidec-Shimpo reducer uses the body steel to directly machine the body, and exerts a large output torque in a compact and sturdy body.

Easy maintenance:Nidec-Shimpo reducer uses high-grade lubricating oil with less friction loss to improve the durability of the lubricating oil, so there is no need to replace the grease during the life of the product.

German quality transmission system

German LROSA-TW grinding helical gear, high precision and durability

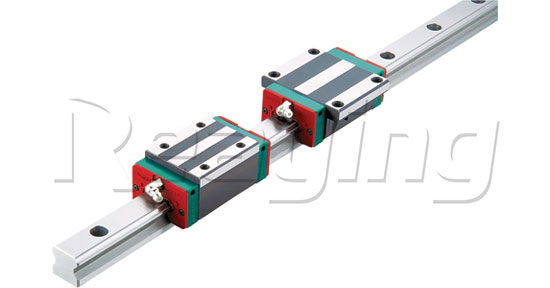

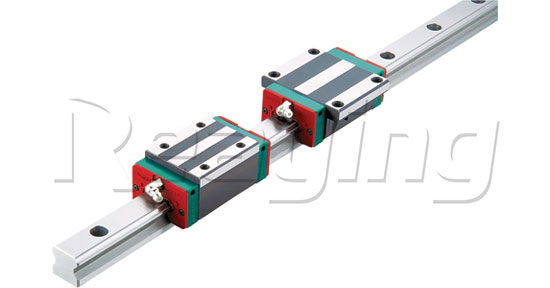

German LROSA-TW linear guide, high speed, high load, high rigidity and high precision. The slider has four-direction load characteristics and automatic self-aligning function, which can absorb the assembly error of the mounting surface.

As the core component of fiber laser cutting machine-laser source, continuous and stable output is more important!

The laser power covers 1000W to 40,000W. The new generation of lasers has higher photoelectric conversion efficiency (>30%), better and more stable beam quality, stronger anti-high-reflection ability, and the introduction of optimized second-generation optical fiber transmission system , To ensure a more stable and precise cutting effect in the cutting of thick plates. The cut sheet has a narrow slit and bright cross-section, which has obvious advantages over other lasers of the same type in the market. And it also has the advantages of high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, strong reliability, long life, and maintenance-free operation.

Metal sheet, pipe cutting, FSCUT laser cutting system is more professional.

Support three levels of perforation, segmentation or progressive combination

Support flight cutting, leapfrog, compensation, introduction of lead wires, micro-joining, pre-perforation, film cutting and other processes

Supports capacitive edge finding, electric focusing, double exchange workbench, automatic typesetting, power failure memory, step back and other advanced function modules

Positioning accuracy 0.001mm, repeat positioning accuracy 0.003mm, maximum speed 150m/min, maximum acceleration 1.5G

Support high-precision/high-efficiency cutting of square tube/round tube/runway type and elliptical stretching tube and angle steel/channel steel

DSP wireless controller, easy to operate, ready to respond to unexpected situations, providing a strong guarantee for safe production

S&A brand dual temperature dual control water chiller

Adopting new imported famous brand compressors and high-flow high-lift S&A pumps, safe and environmentally friendly, saving electricity and durability

Adopt environmentally friendly refrigerant, high cooling capacity and stable working performance

Temperature control accuracy of ±1 °C

With a variety of protection alarm functions, compressor delay protection, compressor over-current protection, water flow alarm, high temperature and low alarm, all-round protection of equipment normal operation

Double pump double temperature to meet different temperature requirements of laser source and laser head

OPTIONAL PARTS

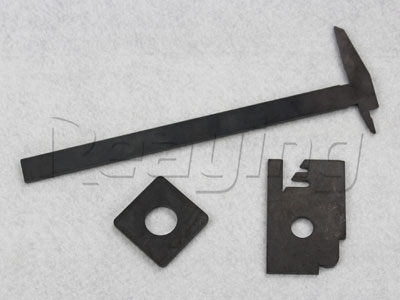

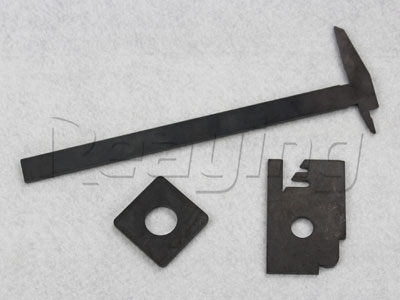

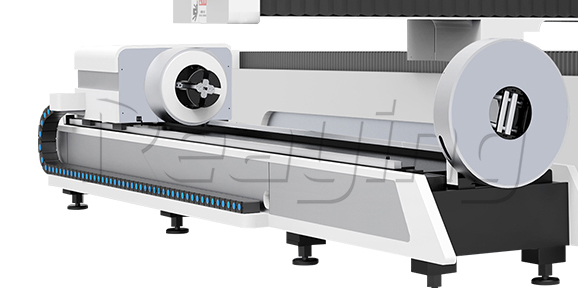

Rotary device for square tube and round tube cutting.

OPTIONAL PARTS

(a) Full enclosed

(b) Exchange working platform

In addition, our machine also equipped:

All of the electrical components are based on Schneider, the world leader in terms of safety, reliability and efficiency.

Intelligent electric oil lubrication device can accurately and timely push grease to each lubrication point, intelligent control, save oil, make the equipment run silky smooth, significantly improve equipment life

Technical Parameters

| Model | RY-L1530F |

|---|---|

| Laser Power | 500W-25000W |

| Working Area | 1500*3000 mm |

| Laser Type | Raycus (IPG / Nlight) Fiber laser source is optional |

| Laser Wavelength | 1064nm |

| Positioning Accuracy | ≤ ±0.025mm/m |

| Re-positioning Accuracy | ≤±0.02mm/m |

| Graphic Format Supported | BMP, JPG, GIF, TGA, Ai, DXF, PLT, PNG, TIF, ai, DXF, DST, etc. |

| Warranty | 5 YEARS |