Fiber Laser Cleaning And Marking All-in-one Machine

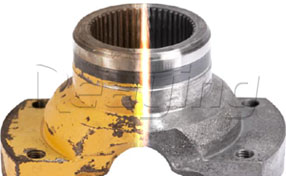

Laser cleaning technology refers to the use of high-power-density laser beams to irradiate the surface of the workpiece, so that the dirt, rust or coating on the surface can be evaporated or peeled off instantaneously, so as to achieve a clean process. This cleaning equipment is a new generation of high-tech surface treatment products, easy to install, operate and realize automation. The operation is simple. It can be cleaned without chemical reagents, medium, dust, and water when the power is turned on. It can remove resin, paint, oil, dirt, dirt, rust, coating, plating and oxide layer on the surface of the object. It has a wide range of applications, including ships, auto repair, rubber molds, high-end machine tools, rails, and environmental protection.

◎Non-contact cleaning, without damaging the base of the parts.

◎Precise cleaning, can achieve precise location, precise size selective cleaning.

◎No chemical cleaning fluid, no consumables, safety and environmental protection.

◎Easy to operate, just power on, and it can be hand-held or coordinated with a manipulator to realize automatic cleaning.

◎High cleaning efficiency, saving time.

◎The laser cleaning system is stable and hardly needs maintenance.

Laser cleaning is mainly divided into: continuous laser cleaning and pulsed laser cleaning

1.Continuous laser cleaning: mainly for the cleaning of oxides (rust, etc.) oil stains on the surface of metal objects. Advantages: strong energy and high efficiency, price is cheaper than Pulsed laser cleaning machine. Disadvantages: The surface material of the object will be slightly damaged.

2.Pulse laser cleaning: mainly for the cleaning of metal and some non-metal surface contamination and oxides. Advantages: good effect, not much damage to the surface of the object. It has strong practicability and can guarantee the precision of precision instruments. Disadvantages: weak energy, low work efficiency, high price.

Model:

RY-CL50

Function:

Metal Clean

Input Voltage:

Custom Made

Laser Power:

1000W / 1500W / 2000W

Laser Source:

Genuines Raycus

Working Area:

Without

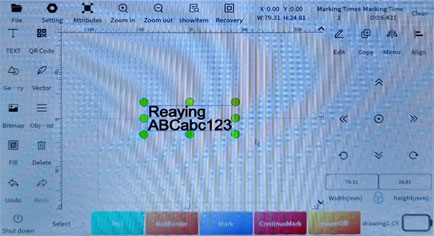

Laser marking interface

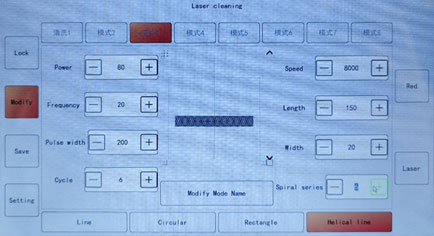

Laser cleaning interface

TWO in ONE Control system

(1) New intelligent marking/cleaning two-in-one laser control system

The system can be used for laser marking and laser cleaning. The software interface is clear, simple and easy to operate; Built-in database system, can save and edit 8 groups of process data; Free adjustment of laser parameters such as laser power and laser repetition rate; With online pulse width adjustment function (if the laser supports), the process parameters can be optimized for the specific situation of the site.

(2) Majestic Gigabit ultra-high performance hardware.

Amlogic S905X3 quad-core Cortex-A55 (2.0xxGHz) processor, 4GB LPDDR4 and 16GeMMC onboard storage 4 USB 3.0 ports, 1 Gigabit network port, port ARM responsible for graphics data processing, FPGA calculation Interpolate the correction algorithm and control the galvanometer and laser in sequence.

(3) The laser control integration of the Linux software system can be carried out through the network port or serial port (USB to 232) for secondary development, and the transmission of simple parameter instructions is complicated System of laser control system integration.

(4) IO control function remote activation marking XY2-100 protocol scanning galvanometer; Fiber lasers such as IPG and JPT, as well as CO2 and UV lasers The control of the device.

(5) Highly integrated system, network port remote landing

Provide remote login tool, remote login graphical operation interface for marking and other functions of control.

(6) Smart phone APP is convenient and faster

Provide a complete secondary development protocol (graphics, galvanometer, laser and other parameters modification).

Laser source

The pulsed fiber laser adopts the JPT brand MOPA structure of the main oscillator power amplification, in which the main oscillation uses the semiconductor laser as the seed source, and the power amplification is realized by the travelling-wave fiber amplifier. MOPA structure pulse fiber laser output pulse beam by directly modulating single-mode semiconductor laser, its pulse width is adjustable, waveform can be edited, has continuous mode, and wide frequency range, high peak power, pulse timing can be accurately controlled with the post-pump, and many controllable parameters, greatly expanding the application range of related pulse laser. Provides an ideal light source for industrial laser cleaning and other applications.

Laser head

Galvanometer lens with high damage threshold, field mirror with high transmittance and large focal depth, meet the long-term operation of high-power laser cleaning; High performance laser galvanometer, fast scanning speed, high precision, combined with professional control software system, to meet a variety of laser cleaning and marking application needs; Galvanometer control optimization, sinusoidal signal control, effectively reduce the galvanometer heat and improve the service life of the galvanometer; provides a variety of cleaning modes: straight, rectangular, circular, positive basalt, double helix and ring, etc., to meet the needs of various application scenarios.

Control panel

Clear functions, easy to operate, equipped with Emergency Stop button.

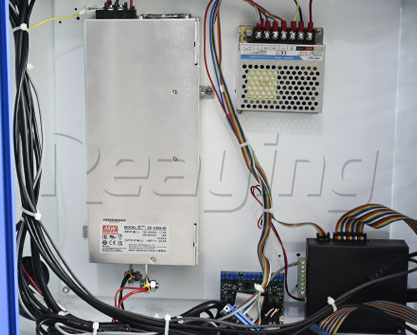

Power supply

Taiwan MEAN WELL regulated switching power supply, with short circuit protection / overload protection / over voltage protection / overheat protection, using lead-free process, in line with environmental protection RoHS requirements.

Technical Parameters

Laser type | Raycus/JPT 100W/200W/300W/500W |

|---|---|

Pulse Formation | Q-Switched |

Average Power (W), Max | 100 |

Average Power (W), Output Range(If adjustable) | 0-100 |

Pulse-Frequency (KHz), Range | 20-200 |

Scanning Width (mm) | 10-175 |

Expected Focal Distance (mm) | 100/160/210 |

Fiber Length (m) | 5 |

Cooling Type | Air cooling/Water cooling |

Input Power | 110V/220V, 50/60Hz |

Power Consumption (W) | 800 |

Dimensions (mm) | 835 X 497 X 925 |

Weight (kg) | 140 |

Pulse energy (mJ) | 1.5 |

Pulse width (ns) | 50-130 |

Repetition frequency range ( KHz) | 20-200 |

Output power adjustment | 10%-100% |

Wavelength (nm) | 1064 |

Operating temperature (℃) | 0-40 |