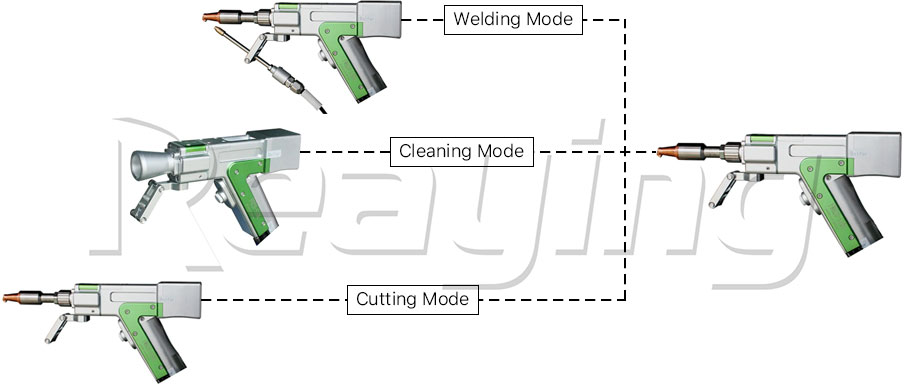

5-in-1 Handheld Fiber Laser Welding Machine – Welding, Cutting, Cleaning in One Powerful Tool

Reaying handheld five-in-one laser welding machine integrates laser welding, laser cutting, laser cleaning, battery welding and welding seam cleaning functions into one innovative device, effectively reducing production and operational costs.

The advantages of laser welding machine are concentrated kinetic energy, zero pollution, small spot welding, wide weldable materials, high application range, high efficiency and fast welding, etc., suitable for occasions with high requirements for welding quality.

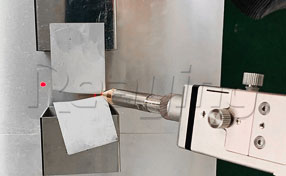

Welding of metal materials:

suitable for steel, copper, aluminum, magnesium, titanium and other metals to achieve high-quality, precision and non-damaging welding effects.

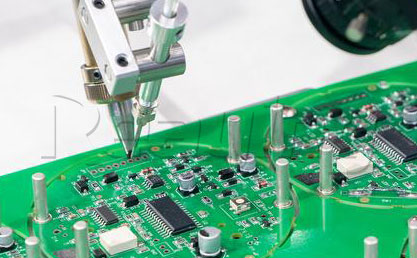

Welding of electronic components:

capable of micro-welding chips, circuit boards etc., using the precision and small heat affected zone characteristics of laser welding to achieve high-quality tiny solder joint welds.

Automobile manufacturing industry:

used in body and engine welding to enhance production efficiency and product quality.

Medical instruments:

surgical instruments, artificial joints etc., are welded with this process.

Sanitary ware:

water pipe joints, reducer joints, tees, valves etc., are welded using this method.

Glasses production:

stainless steel plate, aluminum alloy etc., are precisely welded for glasses buckle structure and frame parts.

Hardware industry:

complex stamping parts like centrifugal impellers or cast iron can be welded with this technology.

Household hardware & kitchen supplies:

stainless steel door handles or electronic components can be efficiently welded with this equipment

Mechanical manufacturing:

fully automated welding processes can be achieved without manual contact.

Auto parts:

can achieve fast welding, full weld, solid welding, simple cleaning, to meet the production requirements of high-end products.

Electronic equipment:

It can break the space limitation and convert the welding Angle at will to ensure the welding quality.

Jewelry industry:

magnify small parts of jewelry through a microscope, achieve precision welding, no deformation after repair.

Aerospace:

can flexibly set parameters to achieve precise welding of complex equipment.

Power battery common welding:

During the intermediate process, tasks include welding the pole ear (including pre-welding), spot welding the pole belt, pre-welding the electric core into the shell, sealing welding of the top cover of the shell, sealing welding of the liquid injection port, etc. The subsequent process involves welding the connecting piece for the battery PACK module and welding an explosion-proof valve onto the cover plate behind the module.

Model:

RY-5IN1

Function:

Welding & Cleaning & Cutting &Welding Seam Cleaning & Battery Welding

Input Voltage:

Custom Made

Laser Power:

1000W-3000W

Laser Source:

Raycus / Max / JPT / DWT

Working Area:

Handheld laser head and control system

Adopt Qilin, Relfa, Chaoqiang quality single-axis swing, dual-axis swing handheld laser head and control system.

● Fiber interface type: QBH/RD can be matched with a variety of fiber lasers.

● Swing pattern can be set point, line, circle, ellipse, triangle, figure eight, semi-circle, circle filling mode, to achieve multi-function welding.

● Double protective mirror, pull collimation focusing, easy to replace protective lens.

● Good sealing, can significantly improve product life.

● High quality optical lenses, can carry 2000W power.

● Scientific cooling system design, can effectively control the product operating temperature.

● Fish scale welding, welding width up to 14MM.

● Can support 2.0 double wire feeding welding

● Process package has storage and call functions.

● English, French, German, Russian, Spanish, Portuguese, Indonesian, Vietnamese and other languages are supported

Continuous fiber laser

MAX brand, Raycus brand, JPT brand continuous fiber laser adopts water-cooled cooling design, with high electro-optical conversion efficiency, low energy consumption, higher beam quality output and wider modulation frequency range, within a certain range, you can modify the frequency and duty cycle of the output laser for a variety of combinations and combinations to meet different application effects, fiber flexible conduction output, free regulation maintenance, easy to integrate customers. It is the ideal light source for industrial laser cutting, welding and other applications.

● High photoelectric conversion rate

● High quality beam output

● Fiber length and core diameter can be customized

● Real-time output power feedback, power closed-loop compensation

● Adjustable frequency range (1-50KHZ)

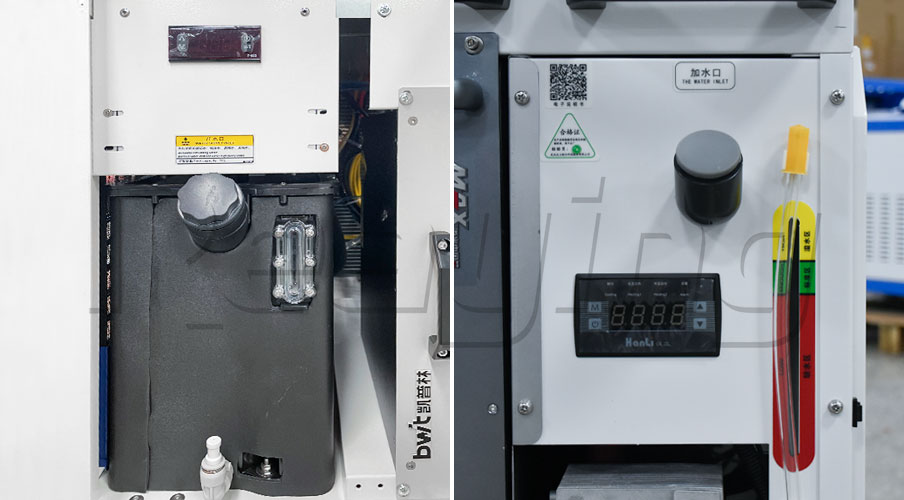

Optional Integrated industrial chillers

Integrated industrial chillers are specially designed for hand-held laser welding machines by the manufacturers of Special Domain and Hanli chillers. It has a dual cooling loop that cools both the fiber laser and the optics/laser gun. Industrial chiller with excellent workmanship, efficient refrigeration, easy installation and maintenance, is the ideal cooling device for handheld laser welding machine. The all-in-one industry is user-friendly because users no longer need to design a housing to mount the laser and rack-mounted chiller. Built-in industrial chiller, laser and control system installed on the top or right side, constitute a portable, mobile handheld laser welding machine. The Laser gun Holder & Cable holder can easily place the laser gun and cable, saving space, and can be easily carried to the machining site in a variety of application scenarios.

● Integrated design, space saving, easy to carry

● Double cooling loop, double temperature and double control

● Active heat dissipation, low temperature heating

● Environmentally friendly refrigerant, stable performance, reliable quality

● Energy saving, maintenance free

Wire feeder

Wire feeder adopts high-power motor, fast wire feeding, wire feeding precision, improve welding efficiency. Double drive wire feed, large thrust, more stable wire feed. With brake resistance disc shaft to prevent loose welding wire when the motor stops. Body with sliding wheel, easy to move. Large storage and wire feed capacity, ready to go. To deal with the problem of excessive weld, double wire feed and three wire feed configurations can be selected.

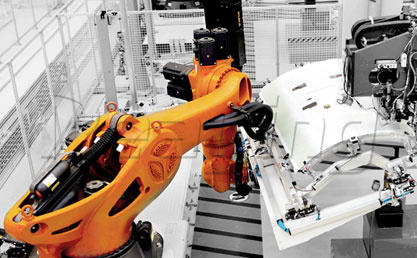

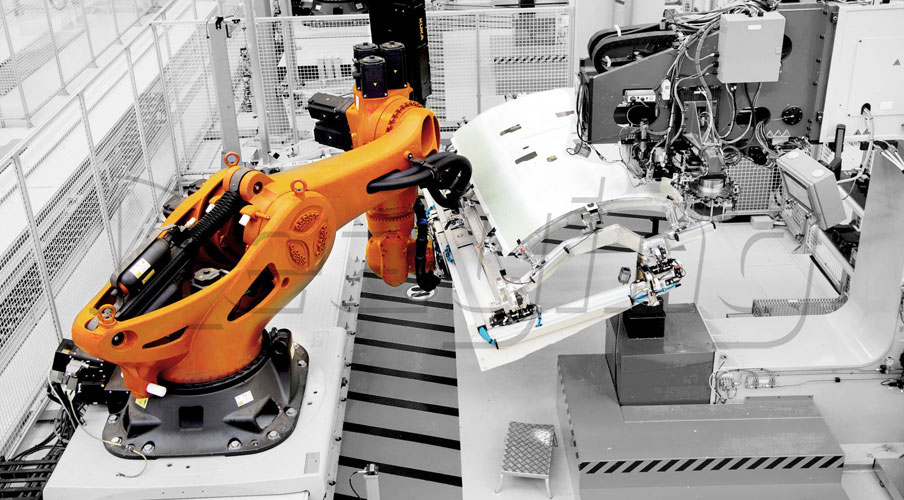

Optional

The characteristics of Reaying welding robot, such as high safety, flexibility and cooperation with people, have greatly attracted manufacturing enterprises to introduce collaborative robots into the production line to achieve a more intelligent and flexible manufacturing process. The advent of the Reaying welding robot removes the barrier of human-machine collaboration, which can work side by side with humans and ensure the safety of the surrounding area. Whether it is automotive manufacturing, aerospace, metal processing or hardware manufacturing, Reaying welding robots are easy to take down.

Technical Parameters

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Source | Fiber Laser Manufactured by Raycus / Max / JPT / DWT | |||

| Wavelength(nm) | 1064 - 1080 | |||

| Laser Mode | Continues | |||

| Length of Fiber | 5-10m (customized) | |||

| Welding Width | 0.2-5mm (adjustable) | |||

| Laser Preview | Integrated Red Light Preview | |||

| Cooling | Water Cooling | |||

| Language | Chinese / English / Russian / Korean / Vietnamese | |||

| Power Supply | AC 220V, 50Hz/60Hz | AC 380V, 50Hz/60Hz | ||

| Parameter Setting | Touch Panel | |||

| Welding Materials | Carbon Steel, Stainless Steel, Aluminum, Brass, Alloy etc. | |||

| Welding Speed | 0-120mm/s (adjustable) | |||

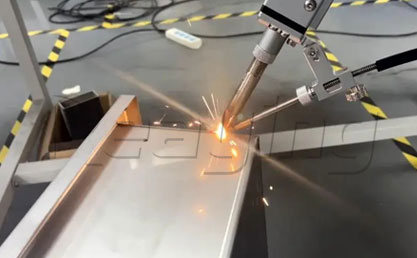

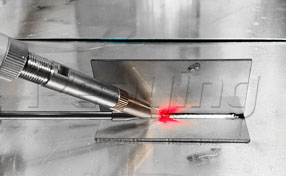

Distribution of welding effect

It has high stability, less maintenance, more energy saving, fast welding speed and high efficiency and other advantages. No deformation, no blackening, large welding depth, firm welding, no need to grind, simple operation.

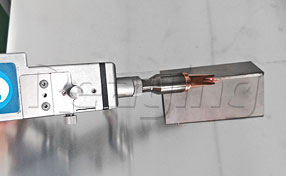

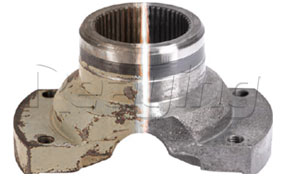

Cleaning effect display

Metal surface rust removal, paint stripping treatment, oil cleaning, painting, coating cleaning, welding surface, spraying surface Dispose. Small laser cleaning head, light and convenient, can work for a long time, power supply can run. No consumables, no damage, no pollution

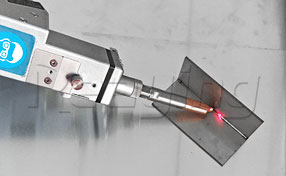

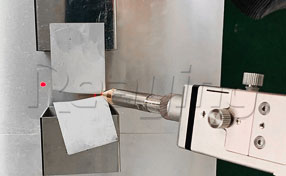

Cutting effect display

As a three-in-one product, it will meet the cutting requirements of welding materials, and the specific cutting speed is simple and convenient features.

Welding Seam Cleaning effect display

Mechanical post-weld cleaning typically involves processes like grinding,polishing,and scraping. While effective in removing post-weld oxides,residual impurities,this approach’s relative coarseness may inadvertently inflict damage on welded joints,resulting in lower work efficiencies. Laser-cleaning technology offers numerous benefits including heightened precision,elevated operational efficiencies,and eco-friendly attributes,making it an optimal choice for post-weld cleansing. Laser-cleaning provides several advantages:

1. High-efficiency & Precision:It swiftly eliminates impurities from welded joints (e.g.,oxides,oil,rust) while enabling precise targeting to prevent collateral material damage surrounding welded areas.

2. Non-Contact Cleansing:Laser-based methods minimize physical harm to welded joints,a critical feature especially beneficial for sensitive materials.

3. Environmental Sustainability:In contrast to traditional chemical cleansing approaches,laser-cleansings are more environmentally friendly,reducing harmful chemical emissions without necessitating chemical agents’ usage.

4. Extensive Applicability:Laser-cleaning machines are versatile across diverse materials,weld types encompass metal/plastic/composite materials among others.

5. Control Capability:The operator retains control over power,speed,focus adjustments,enabling adaptability across varied weld types/materials.

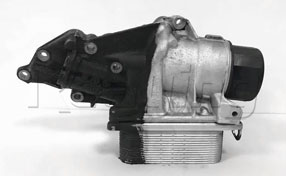

Battery Welding effect display

Various process optimizations can significantly reduce welding defects in different battery types during laser welding. Additionally,the use of advanced laser technologies like oscillating beam and pulse waveform modulation further enhances overall welded joint quality. Front-end optimizations not only offer fundamental support for advancing battery-welding industry,but also enhance real-time productivity when combined with intelligent welding techniques,to ensure seamless production consistency,and operational efficacy.