One of the laser cutting machine automatic programming nesting steps

Laser cutting machine automatic programming nesting software is specific designed for automatic programming of NC laser cutting machine and computer aided manufacturing software, it includes drawing, programming, nesting (layout), correction, and NC code output, component and material management module.

Laser cutting machine automatic programming nesting software is based on CAD/CAM automatic programming nesting software, it can be very convenient to load other geometry (CAD) generated by the system, such as DXF, DWG, IGES, etc.

Some of its specific features include laser cutting machine cutter line set, punch set, micro connection, etc., to meet the many requirements of laser cutting.

Laser cutting is usually use a variety of fixed size plate to cut their required for different parts.Through the automatic programming nesting nesting programming software, will be cutting thickness, material and process the same artifacts, according to certain rule, automatically or manually is arranged on the plank material, and generate the cutting process of the program.Automatic programming nesting sheet can improve the production efficiency and utilization.

Laser cutting machine automatic programming nesting step # 2

Laser cutting machine automatic programming nesting steps as follows:

To save part drawing for programming nesting software can identify the format of the (usually in the form of DXF or IGS) and then into the nesting software programming.

Will pour into the parts according to the different material and thickness of the classification.

According to the material and thickness of the required cutting plate.

According to the choice of the material and thickness of material production set different workpiece cutting process, including lead, compensation, working edge, micro connection, etc.Automatically or manually set of materials, because of the complexity of the laser cutting parts, we usually use automatic nesting, but also can be modified according to the need to manually.

Generate the cutting path and according to the need to make appropriate changes.

Cutting path simulation.

To generate machining program (NC) code.

According to the need to appropriate modification (NC) code.

Will be sent to the correct NC code CNC system.

Laser cutting machine Z axis servo mechanism.

Laser cutting machine is very high to the requirement of the z axis servo mechanism, in the aspect of classification.In cutting to detection and control of cutting surface roughness, at any time through the servo motor and ball screw to adjust the height of the cutting head, in order to make sure the focus of the laser focus after over the surface of the sheet cutting position.Due to the distance of the laser focus to the panel will affect the slot width and quality, therefore, request the z axis high detection accuracy, at the same time, the compound machine tool servo speed should be fast.Follow up too fast will cause the cutting head under shock, slow response lag and will cause the cutting head can’t keep up with the beat.

At present, the detection of board processing mainly capacitance, inductance, resistance, laser, infrared and other several ways.Inductive and resistive belong to non-contact sensor;Laser, infrared and capacitive belongs to non-contact type sensor.Capacitive sensors will not occur in the process of motion detection frictional resistance, the most suitable for high-speed cutting sheet metal processing;With laser and infrared displacement sensor is sensitive to materials of reflectivity, cutting processing applies only to some special occasions (e.g., strong magnetic field, strong interference environment).So when choosing sensor, should pay attention to accuracy and adaptability to the cutting material.Installed at the same time, also need to pay attention to the anti-disturbance measures are taken, it will definitely have to strengthen the aspects of the advantages of laser cutting.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

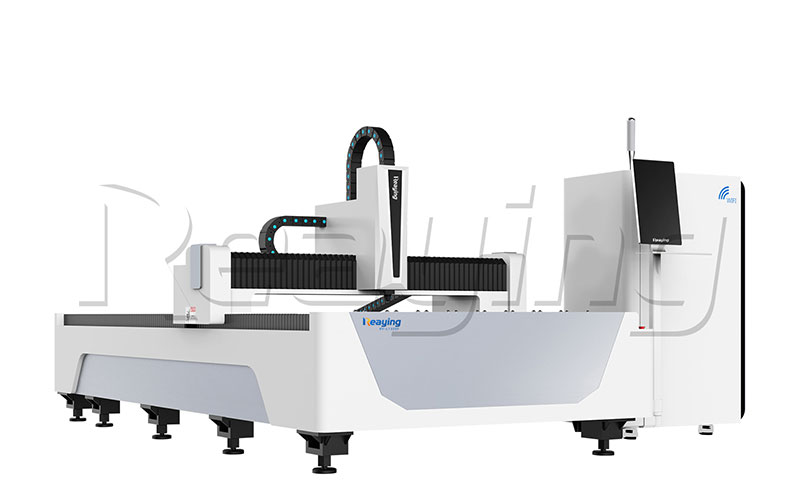

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More