Application of fiber laser cutting machine equipment in the metal pipe industry

Since reform and opening up, China’s rapid development of metal pipe, production and consumption is increasing year by year, the consumption of customers is the pursuit of quality is not too bad, the price is not too high, but in the present stage of metal pipe manufacturing enterprises are now entering a period of sustain loss.

Let enterprises, experienced talent through the cutting of metal tubes that traditional processing methods, because the experience is difficult to control and personnel cost increases, resulting in low cutting efficiency, cutting quality is poor, resulting in serious waste pipe to cut costs.

Plus. In order to solve the disadvantages existing metal pipe manufacturing enterprises, with the metal pipe processing solutions.

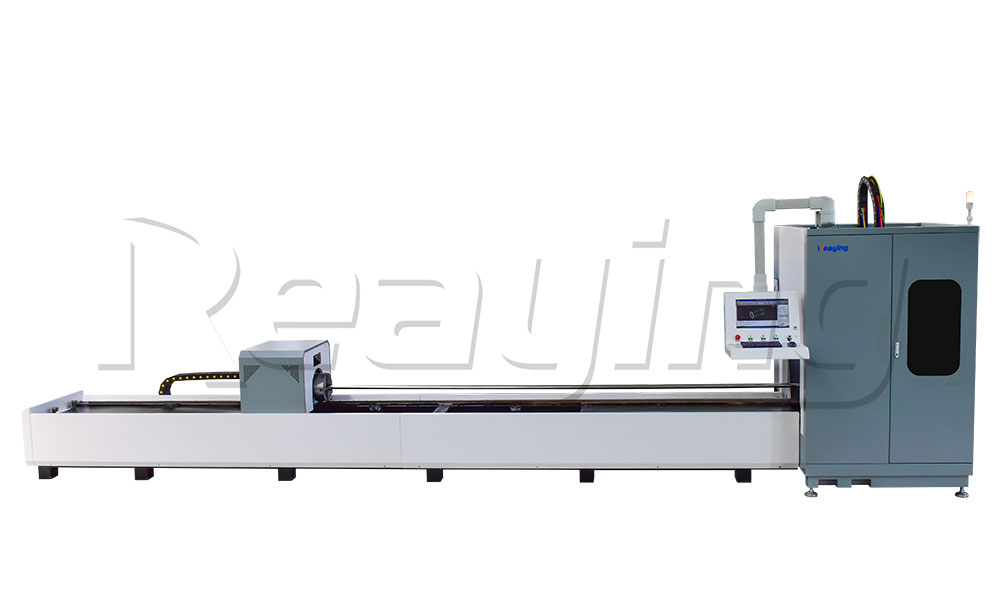

Fiber laser cutting machine to solve the metal pipe mass, high efficiency, high quality cutting way: through our professional pipe cutting nesting software on the computer pre drawing, nesting, feeding segmented programming, the generated cutting procedures, then a metal pipe full stroke automatic cutting laser cutting, cutting technology advanced, reach the metal pipe mass, high efficiency, high quality cutting.

To solve the tube overheating fiber laser cutting machine: the cutting of the pipe will produce slag corresponding attached to the inner wall of the tube, the cutting and produce the most of the heat is absorbed by the material, when the cutting material density is high, it will cause metal.

Overheating pipes, a hot phenomenon serious four angle corner and square tube, seriously affecting the quality of incision, if more serious, will not be able to further cut pipe. To solve this problem, our solution is: let the fiber laser cutting machine, laserHead to ensure in the cutting process, the cutting nozzle and the workpiece surface height remains unchanged, so that the cutting effect is not changed with the workpiece surface, then increase the use of supplementary oxygen pressure, to improve the synthesis speed corners by supporting the control software.

Degree, make the material can be the perfect fast cutting.

Application of small metal laser cutting machine in tube processing area

Application of processing field of pipes and metal laser cutting machine is a very wide application, then we will look together in processing field in pipe of small metal laser cutting machine is what in the end.

A small metal laser cutting machine for cutting, slag soluble cutting the easily attached on the pipe wall, because most of the heat generated when cutting the basic will be absorbed by the material, so when cutting material density is high, often cutting tube over heat phenomenon, resulting in four angle Chu Xiang corner and the RHS serious burning phenomenon, seriously affected the quality of material cutting, even if serious word can make material can not be cut.

For such problems, the following methods can be used to make corrections: first let the cutting nozzle and the material surface height remains unchanged, so that the cutting effect does not appear to change with the surface of the material and the. Then increase the use of auxiliary gas oxygen pressure, so as to improve the synthetic speed pointed by control software.

Professional pipe jacking technology for cutting pipe cutting laser cutting machine, programmable blanking metal laser cutting machine is very complex, if an error occurs, it is easy to cause material waste and cutting efficiency decreased. So we should through the operation of pipe cutting nesting software designed in advance in the computer industry pre drawing, nesting, feeding section of the programming, the generated cutting procedures, then the elongated metal pipe full stroke auto feeding laser cutting.

Only by professional pipe nesting software can realize the CNC pipe cutting machine mass, high efficiency, high quality cutting production, this is the foundation and prerequisite conditions. NC laser cutting technology of CNC laser cutting is a tubular mass, high efficiency, high quality cutting way to produce the most effective, the core of CNC laser cutting is numerical control laser cutting system.

Not only the successful development of the laser equipment with international advanced technology, with self import and export rights, the promotion of products to Hongkong, South Korea, Vietnam, Malaysia, Thailand, Australia, Japan, Germany, Holland, USA, Jordan and so on more than 40 countries, occupy the absolute advantage in international market in the same industry.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More