Efficient and Reliable: CK6132 CNC Lathe Solutions

CNC lathe machines are advanced machine tools that utilize CNC control technology to automate the lathe machining process. These machines are characterized by high precision, efficiency, and a high degree of automation, making them indispensable in modern industrial production.

Compared with traditional machine tools, CNC machine tools exhibit several distinct advantages:

1. Enhanced adaptability to processing objects: CNC machine tools can provide optimal machining methods for mold manufacturing. Unlike conventional machine tools, which require frequent changes in molds, fixtures, and adjustments, CNC machine tools rely on pre-programmed instructions. This makes them ideal for frequent part changes, single-piece and small-batch production, as well as new product development. Consequently, they reduce production preparation cycles and save on process equipment costs.

2. Superior processing accuracy and stable quality: CNC machine tools typically achieve accuracies within 0.05-0.1mm. The digital signal control ensures that each pulse from the CNC device results in precise movements (usually 0.001mm). Additionally, the CNC system compensates for backlash and screw pitch errors, ensuring high positioning and machining accuracy.

3. Consistent and reliable processing quality: When machining identical parts under consistent conditions using the same tool and program, CNC machine tools produce highly consistent and stable quality due to the exact replication of tool paths.

4. High productivity: CNC machine tools significantly reduce both processing and auxiliary times. With higher spindle speeds and feed rates, these machines enable strong cutting at large depths. Furthermore, advancements in high-speed processing allow rapid movement and positioning, along with high-speed cutting, thereby enhancing productivity. Integrated tool libraries also permit continuous multi-process machining on a single machine, reducing semi-finished product handling time between processes.

5. Improved working conditions: Operators need only input programs, edit them, load/unload parts, prepare tools, monitor processing states, and inspect parts. Once set up, CNC machine tools can operate automatically and continuously until completion, greatly reducing labor intensity and shifting the operator’s role towards intellectual tasks.

6. Facilitation of modern production management: CNC machining allows for accurate pre-estimation of processing times and standardization of tools and fixtures. This integration with modern management practices facilitates the standardization of processing information and aligns seamlessly with Computer-Aided Design and Manufacturing (CAD/CAM) systems. As such, CNC technology forms the foundation of modern integrated manufacturing systems, promoting the modernization of production management.

Auto cnc machine programming high precision metal lathe CK6132 for sale uses the design of mechanical and electrical integration,generous appearance beautiful, reasonable structure, easy operation. The machine adopts the integral bed foot, the stability is better. Wear-resistant cast iron after ultra-audio quenching treatment, to ensure the accuracy of the equipment and stability. The fully enclosed cover ensures that a drop of water does not leak out of the machine.

Model:

RY-CK6132

Function:

Turning

Input Voltage:

Custom Made

Main Motor Power:

3.7 kw Servo(3phase 380v 50hz)

Dimension:

2100*1500*1700mm

Net Weight:

1300KG

CNC controller

Standard GSK980TB3

+ Function of conic interpolation, ellipse interpolation, parabola interpolation

+ groove machining cycle instruction function

+ Automatic knife repair function

+ Custom M code (for automatic feed)

+ Adaptive servo spindle, control spindle indexing

+ Front USB port, support U disk file operation and software upgrade

+ A variety of security protection functions, complete data backup and recovery

Optional Siemens 808D

Chuck

Standard: Pneumatic collet

The standard pneumatic collet is a locking device that uses high-quality spring steel to grip the workpiece with high precision machining, and the inner aperture can be customized in various sizes such as round, hexagonal, square, etc.

Optional: Manual 3 jaw chuck/pneumatic chuck/hydraulic chuck

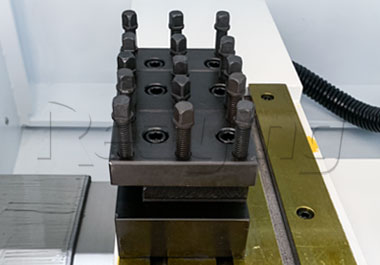

Tool post

Standard gang type tool post

Optional: electric 4 station tool post

Tailstock

Standard: without tailstock

Optional: manual tailstock or pneumatic tailstock

Automatic lubrication

Electric lubrication oil pump, can freely set and adjust lubrication interval

time, as well as lubrication duration

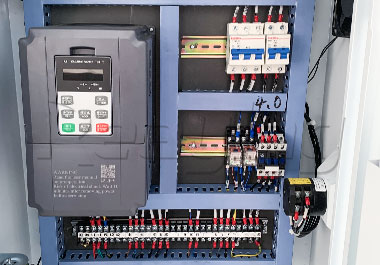

Electric parts

Adopts Delixi, Schneider and other well-known brands at home and abroad components, stable operation, strong anti-interference ability.

Technical Parameters

| Model | CK6132 |

| Max. swing dia. over bed | 320mm |

| Max. swing dia. over cross slide | 130mm |

| Max. processing length | 400mm |

| Dia. of spindle | 49mm |

| Spindle taper | MT5 |

| Through hole dia. of drawing pipe | 41.5mm |

| Spindle tie rod thread | M48×1.5 |

| Spindle speed | 10-3000mm |

| Spindle head type | A2-5 |

| Taper of spindle bore | 21° |

| Tool holder | 3 gang tools |

| Tool bar section | 20*20 mm |

| Main motor power | 3.7 kw servo(3phase 380v 50hz) |

| X/Z axis torque | 4N.M/6N.M |

| X/Z axis travel | 550/400 |

| X/Z axis fast feeding speed | 12/12 m/min |

| Tailstock sleeve travel | 100mm |

| Tailstock taper | MT4 |

| Dimension | 2100*1500*1700mm |

| Weight | 1200/1300kg |