Unlocking the Power of UV Printing: Efficient and Eco-Friendly Digital Printing Technology

As an innovation in the printing industry, UV printing technology is rapidly changing the traditional printing landscape with its high efficiency, multi-function and environmental protection. UV printers use ultraviolet light to cure ink and can print images directly on various materials such as glass, metal, plastic, etc. within a few seconds, which not only improves the printing speed, but also greatly expands the application field.

Model:

RY-1801/RY-1802/RY-1601/RY-1602

Function:

Input Voltage:

Custom Made

Color:

Four color(C/M/Y/K)

Ink tank capacity:

1500ml/ Color

Printing width:

1850mm

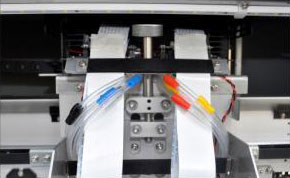

Printhead Introduction

Epson printhead

RY-1602 with two heads ; RY-1601 with one head.

180 nozzles per color, resolution 360*2880dpi;

Higher speed and stable.

Adopt 12FULL smartly printing technolog. Ink droplet changing technology.

Color gradient performance well

Ink droplet volume changing from 1.5pl to 5pl:

Double 4 colors printing, 3 kinds of volume ink droplets(Big, middle, small)jetting alternately, minium droplets 1.5pl, image performance well, without any pellet feeling.

Greyscale level print technology :

Greyscale level print technolgy can achieve better colors, smoother gradient effect, and clear letters/lines and complex details without decreasing print speed.

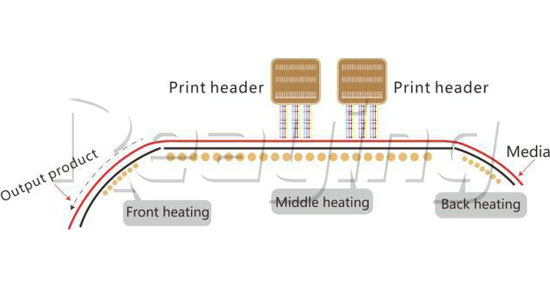

Three-stage heating synchronous control printing platform

Three-area heating system

Automatically heat inks to target temperature, improved inks stainability and stability.

Back heater: Before printing, heat media in advance.

Middle header : Platform heater: Heating media to improve inks stainability.

Front heater: After printing, drying process.

Technical Parameters

| Model | RY-1802 | RY-1801 | RY-1602 | RY-1601 | |

|---|---|---|---|---|---|

| Print Technology | |||||

| Printhead Type | Epson i3200 E1/A1 | ||||

| Printhead Number | Two | One | Two | One | |

| Print Resolution | 1440dpi | ||||

| Printhead height | 2mm-3mm | ||||

| Cleaning | Automatically cleaning, Flash , Moisturized | ||||

| Print speed | |||||

| Different modes | Production 4Pass | 39㎡/h | 20.76㎡/h | 39㎡/h | 20.76㎡/h |

| Precision 6Pass | 24㎡/h | 12.66㎡/h | 24㎡/h | 12.66㎡/h | |

| High quality 8Pass | 20.2㎡/h | 10.59㎡/h | 20.2㎡/h | 10.59㎡/h | |

| Ink system | |||||

| Ink | Type |

Eco solvent ink/ Water based ink/ dye sublimation ink |

|||

| Color | Four color(C/M/Y/K) | ||||

| Ink tank capacity | 1500ml/ Color | ||||

| Supply | Negative pressure CISS Bulk ink | ||||

| Media | |||||

| Printing width | 1850mm | ||||

| Media Type |

PhotoPaper, Cavas, Car sticker, Reflecting materials, PVC film, Sublimation paper |

||||

| Max weight | 40Kg | ||||

| Disposition | |||||

| Take up | Standard | ||||

| Heating system |

Front/ Middle / Back heating, controlled by smart board |

||||

| External Dryer | Synchronous dry fans | ||||

| Operation | |||||

| Language | English/ Chinese | ||||

| PC System | Windows XP/ Win 7 | ||||

| Environment | Temperature:18-25℃ Humidity:35-65% RH | ||||

| Printing | |||||

| Interface | 1000M Network | ||||

| RIP | Maintop/ Photoprint/ Wasatch | ||||

| More | |||||

| Power supply | AC-220V,50Hz/60Hz | ||||

| Power(W) | Min:32W, Max:2300W | ||||

| Noises | Min< 32db; Max<= 65db | ||||

| Machine size(LxWxH) | 2580mm×730mm×1475mm(LxWxH ) | 2380mm×730mm×1475mm(LxWxH ) | |||

| N.W(kg) | 200Kg | 195Kg | 180Kg | 175Kg | |

| Packing size(LxWxH) | 2746mmx750mmx625mm(LxWxH) | 2546mmx750mmx625mm(LxWxH) | |||

| G.W(kg) | 250Kg | 245Kg | 230Kg | 225Kg | |

Application Field Introduce

lndoor and outdoor poster

[Media : Photopaper.PP. Car Sticker、cold lamination film、Indoor Vinyl paper , etc]

Wallpaper making & Decorative Painting

[Media : wallpaper base malerial & oill canvas. non-woven fabric ,etc]

Graphic design

Print out

Outdoor display

Graphic design

Print out

Outdoor display

Sublimation Transfer

[Media:Heat-transfer paper,etc]

Graphic design

Print out

Heat Transfer

Curtain products

Mouse pad finished product

Pillow product

Higher precision at mechanical design

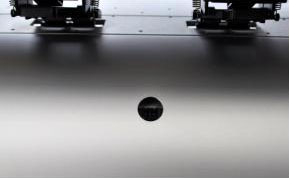

1. Lifting capping station

Capping go up and down with aguid rail , better to capping head.

2. Manul adjustment

Capping station could be adju-stable by manual under the sta-tus of without power supply.

3. Media detector

When media is going to use up,system could pause pri-nting job.

4.Media touching switch

When carriage touch the me-dia,switchs could be on,and system emergency stop printing.

5.Printhead height adjustment

You can adjust the height betw-een head plate and media by manual.

6. Platform adjustable

Platform horizontal level could be adjustable.

7.External fans and heater

One external heater and dryer fans was integrated in one part.

8. Heating control board

Front / middle / back heating co-uld be controlled by a smartboard.

9.Collision capping station

Single head machine adopt coll-ision capping station.

10. Subtank

lnk supply system, stardard inklevel could be kept, and betterink flowing.