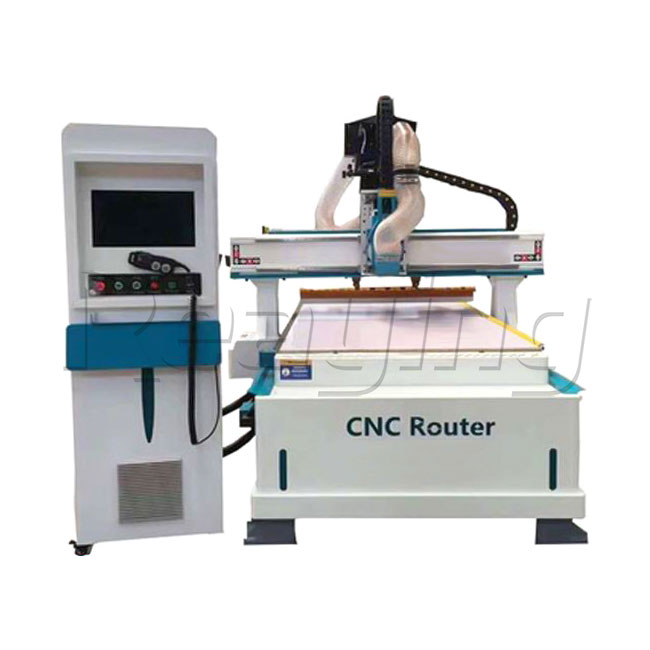

High Quality Woodworking Machining Center 1325 Automatic Tools Changer CNC Wood Router Machine

ATC CNC machining center is the main cutting machine equipment in the customized furniture production industry at present. It has an independent tool magazine, which can automatically replace the required tools during the processing of the workpiece without stopping the work, thus greatly improving the work efficiency.

ATC CNC machining center can cut, carve, drill, wire, slot, cut and mill wood, MDF, acrylic acid, PVC, plastic, foam, stone, soft metal and other materials, and one machine can be used for many purposes.

The linear tool change machining center is mainly used in: wardrobe processing and production, cabinet processing and production, sliding door processing and production, indoor door processing and production, office furniture production, panel furniture production, and whole-house customized furniture production. It can cooperate with automatic loading and unloading platform, automatic labeling machine, automatic edge banding machine and CNC side hole machine to form an automatic panel furniture production line.

Model:

RY-C1325B

Function:

Engraving & Cutting

Input Voltage:

Custom Made

Spindle Power:

9KW

Spindle Type:

Air Cooling/ Water Cooling

Working Area:

1300*2500mm

Five-face milling of bed

The whole machine is made of heavy high strength steel, and the bed is simmered with aging treatment. After that, it is finished by the five-face milling machining center. According to the mechanical principle, the reinforcement treatment at the main stress position can bear the maximum weight of various plates. The processing method and process shall ensure that the parallelism of the track and rack surface, and the parallelism of the gantry and the bed are controlled within 0.02mm. Manual drilling can avoid the problem that the perpendicularity of the threaded hole is not up to standard caused by the machine tool’s failure to clean the hole position after drilling and the direct threading, and ensure the high accuracy of the perpendicularity of the threaded hole. The whole machine adopts the secondary assembly process, in which the mechanical accuracy is determined by the first assembly, and the secondary assembly enters the quality inspection process. Through calibration and detection, it ensures the machining accuracy and the stable operation of the machine body.

9KW air-cooled spindle for tool changing

High-power automatic tool change air-cooled spindle, with a maximum speed of 24000 RPM/min, low vibration, low noise, large cutting force and high precision. Not only is the material surface fine without sawtooth when carving, but also the bottom surface is flat and smooth, and the contour is clear.

Frequency converter of spindle

It has the advantages of miniaturization, high function, high reliability and easy installation, and transforms every input of industrial resources into fruitful results. The optimized structure and lock-free screw terminal design provide convenient maintenance process and save installation and maintenance time. Friendly user interface, through use selection, you can easily complete parameter setting. Built-in USB function enables faster parameter copying and improves production efficiency.

12 positions linear tool magazine

The standard 12 tool magazine can be equipped with various types of tools to achieve multi-process processing requirements. The tool change is fast and smooth, greatly improving the work efficiency.

Control system

The SYNTEC/LNC/Weihong all-in-one machine control system: the CNC system of well-known brands at home and abroad has fast data processing speed, stable operation, convenient operation, simple and fast, easy to learn and use, and powerful functions, which ensure the processing accuracy, operating speed and safety visibility of the equipment. The all-in-one machine control system has the breakpoint, power failure and engraving function, and the automatic error correction function of returning to the original point, which effectively guarantees the processing accuracy in all-weather operation, It supports U-disk operation, avoids computer virus interference, has high reliability and efficiency, and is easy to learn. It has intelligent processing boundary protection function to prevent mechanical collision caused by the design layout exceeding the processing range; Intelligent processing speed control can control the processing speed, truly improve the processing efficiency, extend the tool life and improve the yield. Strong compatibility, suitable for various CNC software: cutting software, door panel software type3, Artcam, Castmate, Pore, Wentai, various CAD/CAM software.

Servo motor

Japan’s Yaskawa/Taiwan’s Delta/Shenzhen LEADSHINE high-power pure servo drive motor has large torque, high precision and fast speed, ensuring the processing speed and stability of the equipment. Z-axis adopts band-type brake motor, which can protect the head of the equipment from slipping after power failure and maximize the safety performance of the equipment.

Linear guideway and rack transmission system

Taiwan’s high-precision square linear guide rail has high accuracy, long service life, large contact surface, strong load-bearing capacity, and vertical rail technology can better ensure the operation stability during installation. The guide rail material is made of bearing steel, which is much higher in quality, wear resistance and hardness than most square rails made of 45 # steel on the market. The precision of grinding rack can reach level 5, the error of lead tooth pitch is 0.003mm, and the cumulative error is 0.035mm (1000mm length). It has excellent performance in material, heat treatment, precision, surface roughness, bearing capacity, noise and other aspects. It ensures high rigidity, high precision, long service life, easy installation, maintenance-free, and stable transmission under long stroke and heavy load.

Electronic components

The electronic components of the whole machine are genuine Chint electronic components. The electrical design of the whole machine conforms to the European Union CE standard, with strong impact resistance, anti-interference, moisture-proof, dust-proof and stability, to ensure the stable processing and operation of the equipment for a long time. The control box uses high-flexible bending resistant cables and is loaded with advanced open circuit protection, overload fault alarm and other multiple interactive protection measures. The wiring is neat and clear, which improves the safety of the equipment.

Independent six-zone PVC vacuum adsorption platform

The thickened vacuum adsorption table is adopted, and the six-zone design can strongly adsorb plates of different sizes and materials, which has strong versatility and also reduces the waste rate of plates. The function of patching board is specially added, and the patching board with small materials is simple and convenient, and does not run.

7.5KW water-sealing vacuum pump

The vacuum pump adopts high-quality copper wire motor, with high negative pressure, small flow and stable operation. Low noise, small size, light weight.

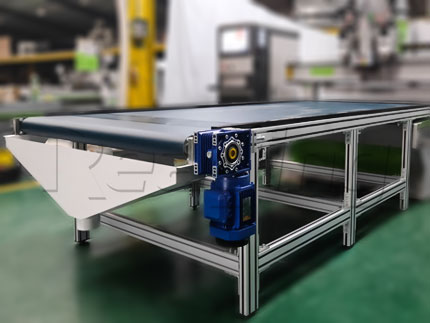

Pushing system and secondary dust removal

This machine is equipped with a material pushing system, which automatically pushes the material after the whole machine is finished. At the same time, the material pushing and dust suction switch automatically removes the dust on the table, saving the trouble of manually cleaning the table! It saves time and labor and is convenient for picking up materials after processing.

Positioning cylinder

Before starting work, we need to locate the workpiece origin of the plate to be processed. If there is no positioning cylinder, we need to repeatedly adjust the positioning of each plate to ensure the processing accuracy and accuracy. After installing the positioning cylinder, we can ensure that the position of the material placed on each plate is the same, without having to define the workpiece origin repeatedly, which is easy to operate and saves time. The horizontal and longitudinal positioning cylinder can quickly locate the plate to be processed, reduce the time for manual positioning of the plate, and improve the feeding efficiency.

Automatic oil filling system

The automatic oiling time can be set according to the working intensity to ensure the lubrication of the slide, guide rail and lead screw, extend the service life and improve the working efficiency.

Double-barrel vacuum cleaner

It is equipped with a 5.5KW high-power double-barrel vacuum cleaner, which has good dust collection effect. The secondary dust collection of the pushing material is clean and in place. After the processing, the material is directly loaded, and there is no need to clean the table manually.

Automatic tool setting

Convenient and flexible automatic tool setting. Intelligent CNC Router equipment, just for easier operation.

Optional

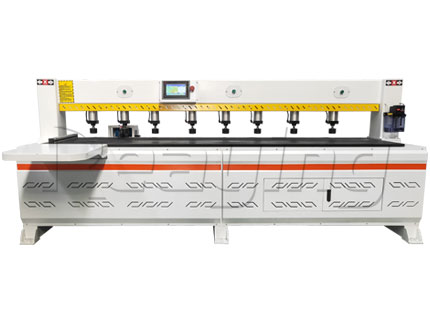

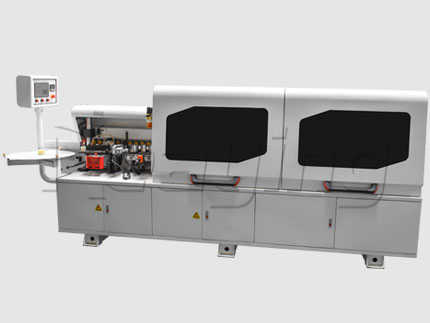

It can be equipped with automatic loading and unloading system, side drilling machine, automatic edge banding machine, vacuum laminating machine and other equipment to form a complete panel furniture production line.

Technical Parameters

| Model | RY-C1325B ATC with disc tools magazine |

|---|---|

| X,Y,Z Working Area | 1300x2500 mm |

| Table size | 1700*3300mm |

| Table structure | Independent six-zone PVC vacuum adsorption platform |

| Frame | Heavy duty seamless welding bed |

| Transmission | X&Y axis high precision grinding grade helical teeth rack plus linear guide, Z axis ball screw plus linear guide with lock brake |

| Spindle | 9.0KW air cooling spindle |

| Spindle Speed | 24000r/min |

| Drive Motors | LEADSHINE servo motors and drivers |

| Frequency converter | BEST brand |

| Working Voltage | AC380V, 3Ph, 50Hz |

| Controller system | LNC WM2200 with DSP controller |

| Travelling speed | 95m/min |

| Working speed | 12-30m/min |

| Tool magazine | Tool magazine |

| Vacuum pump | 7.5KW water-sealing vacuum pump |

| Dust collector | 5.5KW double bags dust collector |

| Electrical component | DELIXI with high flexibility shielding cable |

| Others | 3+2 positioning cylinder, automatic oil filling system, automatic tool setting, second push and second dust removal, feeding auxiliary roller |