Advantages of laser welding machine in different metal welding

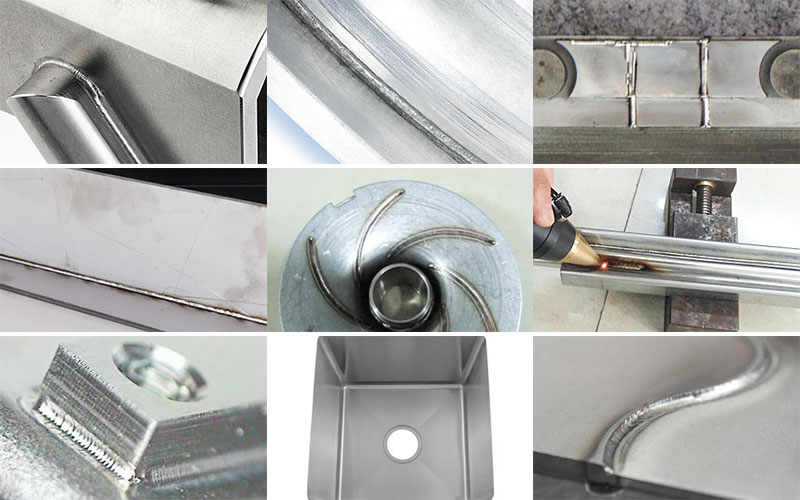

Laser welding technology is a new industrial technology revolution. It leads this industrial age with its unique welding method. Laser welding machine can weld refractory materials such as titanium, etc., and can weld heterogeneous materials with good effect. And its welding Fast speed, large depth, small thermal deformation. Let’s learn about the advantages of laser welding technology in welding different metal materials.

Before understanding the advantages of laser welding technology in welding different metal materials, first introduce the difficulties encountered in welding different metal materials.

- The greater the difference between the melting points of different types of metal materials, the more difficult it is to weld.

This is because when the material with a low melting point reaches a molten state, the material with a high melting point is still in a solid state. At this time, the melted material is easy to penetrate into the grain boundary of the superheated zone, which will cause the loss of low melting point materials, alloy elements burning or evaporation. Make welded joints difficult to weld. - The greater the difference between the linear expansion coefficients of different types of metal materials, the more difficult it is to weld.

A material with a larger linear expansion coefficient has a larger thermal expansion rate and a larger shrinkage when cooling, and a large welding stress will be generated when the molten pool crystallizes. - The greater the difference in thermal conductivity and specific heat capacity of different types of metal materials, the more difficult it is to weld.

The thermal conductivity and specific heat capacity of the material will deteriorate the crystallization conditions of the weld metal, severely coarsen the grains, and affect the wettability of the refractory metal.

The laser welding machine solves the problems in the welding of different metal materials well. The extremely high cooling rate and small heat-affected zone of laser welding create favorable conditions for the compatibility of materials with different structures after welding and melting of many different metals. The metal composite parts manufactured by laser welding machine welding method can not only make full use of the excellent performance of each component material, but also greatly reduce the production cost and give full play to the performance of the material.

Advantages of laser welding machine in welding of different metal materials:

- The focus of the laser beam for laser welding is small and the output power density is high. It can laser weld some alloy products with high melting point and high strength.

- Processing Laser welding is a non-contact type in the production and processing process, and there is no special tool loss and special tool replacement. The kinetic energy and moving speed of the laser beam can be adjusted, and many different laser welding processes can be performed.

- The degree of automation is high, computer adjustment can be realized, the laser welding speed is fast, the efficiency and function are high, and other complex laser welding can be easily realized.

- Narrow pulse width, small heat-affected zone, suitable for sheet welding.

- It is a product workpiece in a vacuum environment container and a product workpiece inside a complex structure, which can be laser welded by a glass ionization laser.

- The laser beam is easy to guide and focus, and can realize multi-directional transformation.

- Compared with laser welding and electron beam processing, there is no need to write strict vacuum technology system software, and the actual operation is convenient.

- The frequency and pulse width can be adjusted in a wide range, which can meet the welding requirements of more materials.

The above are the advantages of laser welding technology in welding different metal materials. The welding of materials is divided into welding of the same material and welding of different materials. The laser welding machine uses high-energy laser pulses to locally heat the small area of the processed material. The powerful energy of radiation diffuses to the inside of the material through heat conduction and melts the material, so while the same material is perfectly welded, the welding of dissimilar materials can also achieve a perfect effect of pollution-free, and there is no need for post-welding treatment or only simple treatment , High weld quality, no porosity, controllable positioning accuracy, easy to realize welding automation. Laser welding has high production efficiency, stable and reliable processing quality, and good economic and social benefits. In an era where new equipment, new materials, new technologies and new processes are emerging and constantly updated, producers must not only understand the characteristics, advantages and requirements of laser welding, but also recognize many innovations and future trends in this field. Only in this way can they grasp Technology trends can always be at the forefront of the times.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More